Zinc liquid purifier is a new product specially developed by our company by organizing professional technicians in combination with the actual situation of galvanizing production.

Zinc liquid purifier is a new product specially developed by our company by organizing professional technicians in combination with the actual situation of galvanizing production. It can effectively remove suspended impurities in zinc solution, reduce zinc particles contained in zinc ash to zinc solution, improve the fluidity of zinc solution, reduce the content of iron ions in zinc solution, and eliminate slag hanging, nodulation and sticking on the surface of plating parts. The quality of zinc solution is greatly improved, the surface of galvanized products is bright and smooth, and the grinding workload of galvanized products is greatly reduced. This product has been widely used by many manufacturers.

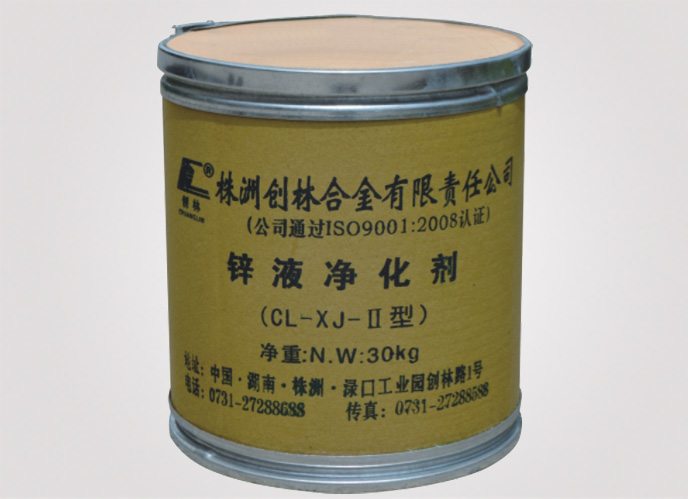

CL-XJ-II;

Above 430 C;

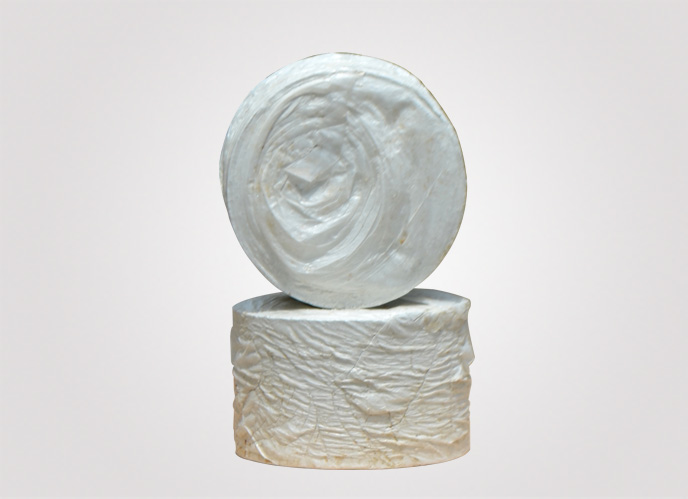

1. According to the size of the zinc pot, a self-made porous purifying box with locks (see figure);

2. The use of zinc purifier is 0.02% (e.g. 5 tons of zinc plus 1 kg of zinc purifier);

4. Place the zinc purifier in the porous purifying box;

5. Insert the porous purification box into the depth of 1/3-2/3 and move along the direction of the zinc pot until the boiling is over;

6. Repeated purification process 2-3 times according to impurities;

7. Salvage the zinc ash on the surface of the zinc pot and keep the liquid zinc for about 1 hour, then normal production can be carried out.

Paper drum packing, lined with plastic bags, 30kg per barrel, 500g per small piece.

1. The zinc level in the zinc pot keeps a certain distance from the edge of the pot (about 100 mm);

2. Operators must wear protective equipment to prevent zinc splashing and scalding;

3. Completely do the pretreatment work, eliminate harmful impurities into the zinc pot;

4. Pay attention to moistureproof storage.

The product has strong degassing and inclusion removal ability, and can significantly reduce the degree of inclusions and pinholes in castings. The aluminium slag has good separation and slag cleaning property.

The product has strong degassing and inclusion removal ability, and can significantly reduce the degree of inclusions and pinholes in castings.

The product has strong degassing and inclusion removal ability, and can significantly reduce the degree of inclusions and pinholes in castings. The aluminium slag has good separation and slag cleaning property.

This product has heating characteristics in use, fast slagging speed and easy slagging. It has excellent separation property of slag and aluminium, and can effectively separate aluminium from slag. The slag is not agglomerated and the aluminium content in slag is very small.

This product has heating characteristics in use, fast slagging speed and easy slagging. It has excellent separation property of slag and aluminium, and can effectively separate aluminium from slag. The slag is not agglomerated and the aluminium content in slag is very small.

Scanning Two-Dimensional Code Sharing to Wechat